Global Manufacturing Sourcing & Optimization

Rapid product development requires a multi-disciplinary team employing DFM considerations from the outset. Understanding the product’s intended production volume, manufacturing method, and material choice can all impact the final design and order of assembly, so our team at Acorn collaborates early with suppliers. Acorn works with clients to identify the best CM for each product’s unique requirements. We transfer our in-depth knowledge of a product’s design – from identifying critical to function dimensions, and tolerances analysis, to the impact on the product if changes are requested by a CM to improve manufacturability/yield. We keep these aspects in mind throughout every stage of our proven development process, to prevent rework and ensure a smooth transition into the manufacturing phase.

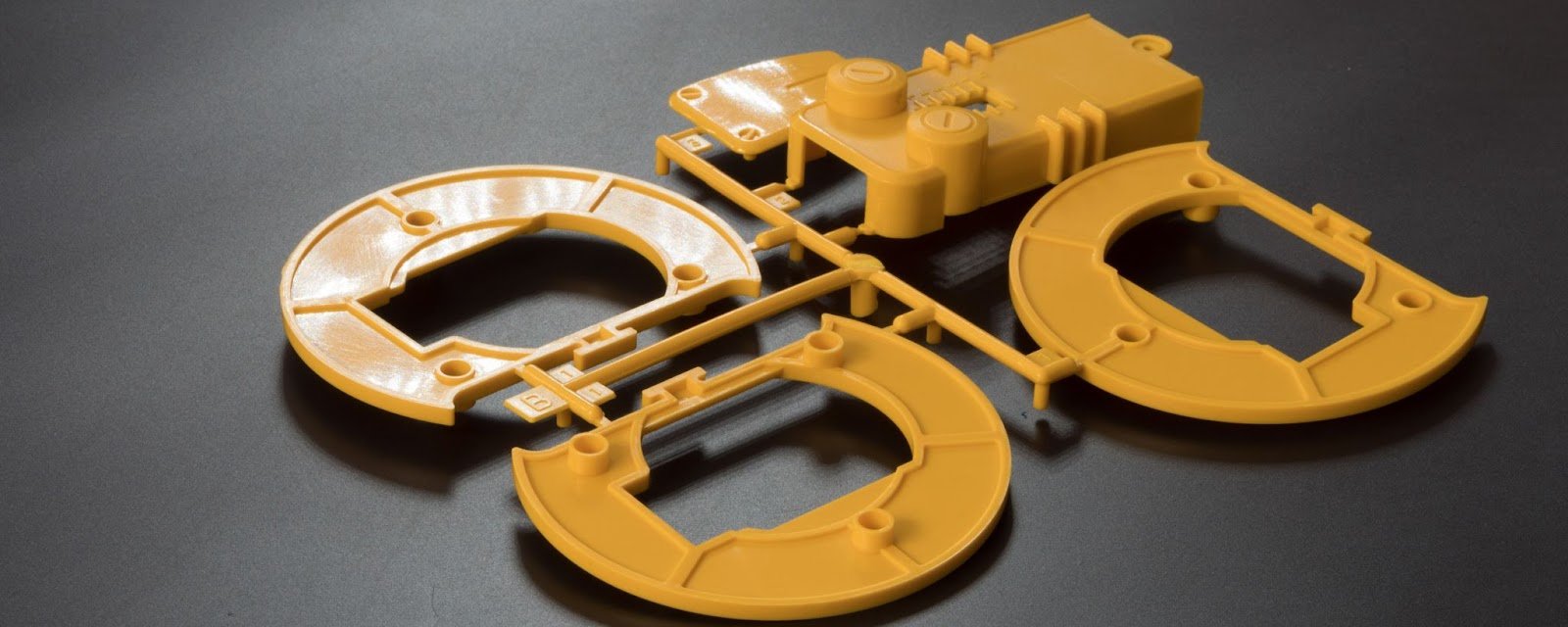

Rapid Prototyping

A well-designed prototype allows a design to be flushed out and feasibility tested before moving into expensive full-scale manufacturing processes. Acorn can implement a variety of low-volume and low-cost manufacturing methods allowing important discoveries to be made while avoiding expensive production tooling reworks.

Assembly

CNC plastic and metal

3D print plastic, Rubber and metal

Sheetmetal

Silicon mold casting

Molecule and laser bonding (for life science components)

Custom made spring and hardware

Production Services

Acorn provides our clients with assistance when selecting a qualified vendor as well as offers a wide range of services that allow us to work closely with CM’s during the production phase.

ODM and OEM sourcing & qualification including ISO 13485 certified vendors

DFM review

vendor tooling design review

PRODUCTION JIG AND FIXTURE DESIGN AND REVIEW

PRODUCTION ONLINE TESTING SET UP

fixture and on production line testing

inspection tooling and cage design

On site trouble shooting & engineering support

Production KPL set up review

Quality Control

As production ramps up some unknown situations may occur. Acorn Asia Group allows immediate quality control services in order to quickly remedy design flaws and ensure the final product is delivered as expected. This unique offering allows Acorn to provide continuous support till the very end of production.

1st article inspection and qualification

Pilot run inspection and qualification

Production inspection and qualification

Value Engineering

The aim of value engineering is to minimize the overall cost of production without affecting the quality of the product. Acorn provides this service to help clients to reduce the cost of both new developing and existing products.

EXISTING PRODUCT COST AND FUNCTION ANALYSIS

LOW-COST SUBSTITUTE MATERIAL SEARCH AND DESIGN UPDATES

COST REDUCTION ALTERNATIVE VENDOR SOURCING

Overseas Capabilities

it’s critical that the CM and design team work closely to both transfer the knowledge of the design to the CM, along with working through potential issues as manufacturing volume starts to ramp. This is particularly important if you’re planning to manufacture in places such as China, where distance and cultural/language differences are things to contend with. Acorn Asia group was established in 2004 with this in mind and has since strengthened our resourcing and quality control capabilities. Our talented Asia-based engineering team has built a large supplier database from prototyping to production. This has allowed us to stand out from competitors by offering trusted resources capable of producing rapid and high-quality results.

Schedule a Free Consultation

During Acorn’s 30 years of development experience, we have created a complete list of offerings to help our clients effortlessly navigate the production phase.

Transitioning to manufacturing is most successful when the conversation with the manufacturing team is started as early as possible in the design. So don’t wait, reach out to Acorn today for a free consultation.

Frequently Asked Questions

-

No. Although we do NOT own any manufacturers, we work closely with contract manufacturers offering a range of services to meet our clients’ cost and time objectives.

-

It is very common for Clients to already have established vendors when they engage with Acorn. We work with them to understand their current process and resolve any existing errors or concerns. This working relationship bewteen vendors, clients, and our design team is key to the success of a product.

-

The design and prototyping phase (Phase 2) is typically when engagement with a vendor begins. This early engagement allows a product to progress by leveraging both the goals of the design team and the needs of the vendor. If you need assistance selecting the right contract manufacturer for your product, Acorn has a complete list including ISO 13485-certified vendors.