Product Engineering

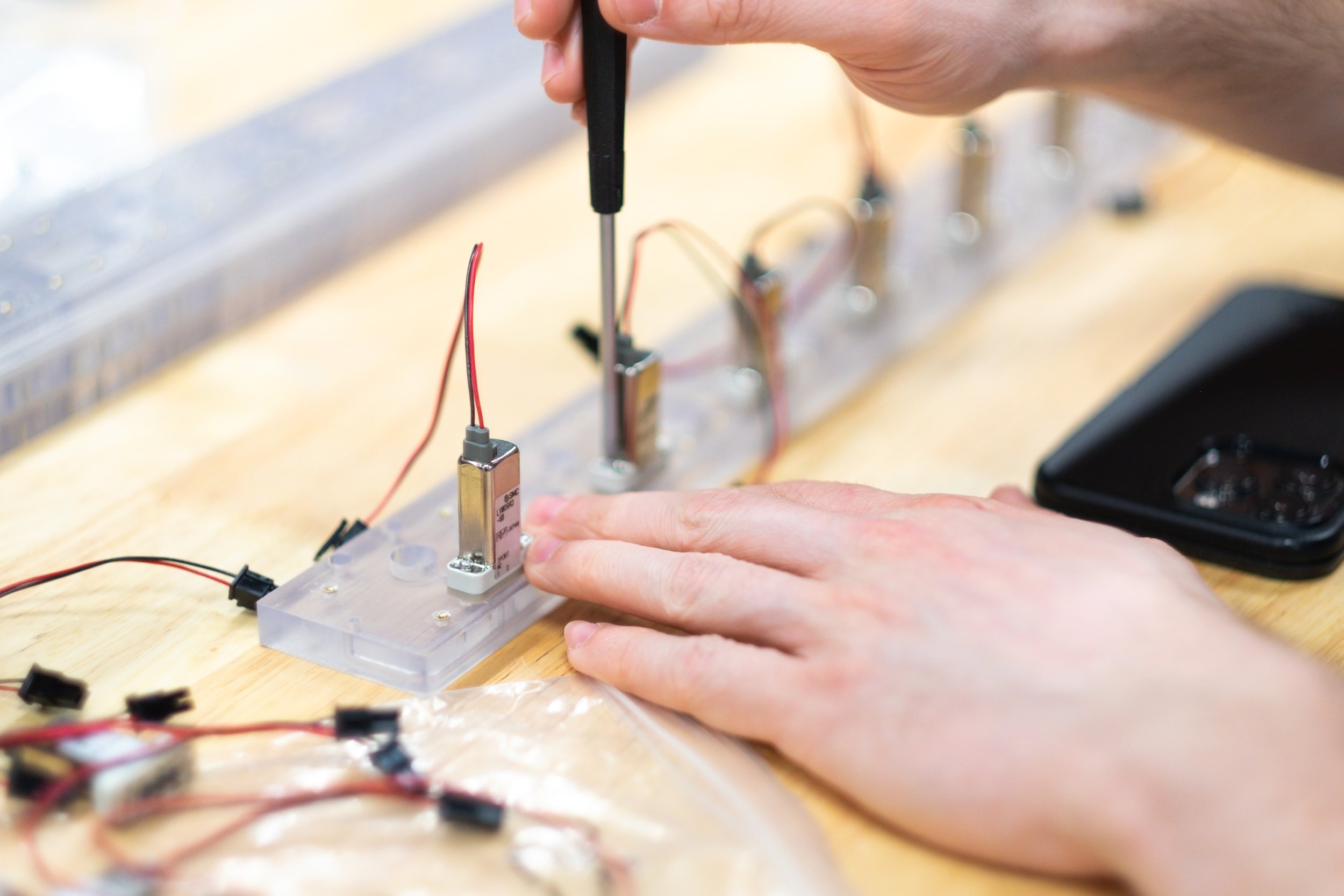

Engineers are called upon to design and deliver products. They ideate, design, build and test their concepts within industry standards and program goals. We produce concepts, mechanisms, and prototypes for medical, robotics, life science, and consumer industries. Tasks include concept creation, mechanism design, electronics packaging, engineering analysis, prototyping, testing, design for manufacturing, and production support.

Concept Development

Engineers & designers bring a unique blend of technical knowledge, problem-solving skills, and creative thinking to the field of product development. Their ability to conceptualize, design, and prototype products ensures feasibility, functionality, and efficiency in the development process. At Acorn we have a number of tools available that allow us to explore multiple directions, derisk program paths, and document key decisions.

Mechanical Engineering

Electrical Engineering

Embedded Systems & Firmware Development

Design Validation Testing

Production Documentation

Manufacturing Transfer & Bring up

Production Validation Testing

Design For Manufacturability

In House Industrial Design, UX Design, & UI Design Team

Engineering Analysis

Engineering analysis is a systematic approach to evaluating the performance, reliability, and safety of existing products or designs. By employing various techniques and tools, engineers can uncover a multitude of problems and shortcomings in these products. Here's how engineering analysis can reveal issues in existing products or designs:

Finite Element Analysis

Structural Analysis

Thermal Analysis

CFD Analysis

Mold Flow Analysis

Kinematic Analysis

Tolerance Analysis

Engineering Analysis & Hand Calculations

Cost Analysis

Manufacturing Support

At Acorn we understand the intricacies of materials, manufacturing processes, and cost-effective solutions, and use this expertise to optimize designs for practicality and affordability. We offer a wide variety of manufacturing optimization services that make indispensable assets when you need to get a concept to market fast.

Global Supply Chain Development

CM Identification and Qualification

Onsite Vendor Audits

Production Design Support

Production QC Support

Global Prototype Supply Chain

Process Validation Support

Pilot Build Support

Production Line Support

Tooling Reviews and First Article Inspections

Co-located with Asian Manufacturing Base

Expertise Within Reach

Our engineering expertise covers a wide variety of industries including; robotics, life science, healthcare, industrial, and others. Acorn has 30 years of experience bringing unique and complex products to production for diverse clients.

From Prototype to Production, we recognize the importance of engineering detail in all stages of development. Whether you need prototyping or DFM refinements, Acorn’s engineering team will empower you throughout your journey.

Whether you need a full turnkey project plan or just help to get to the next phase, the Acorn engineering team can help.