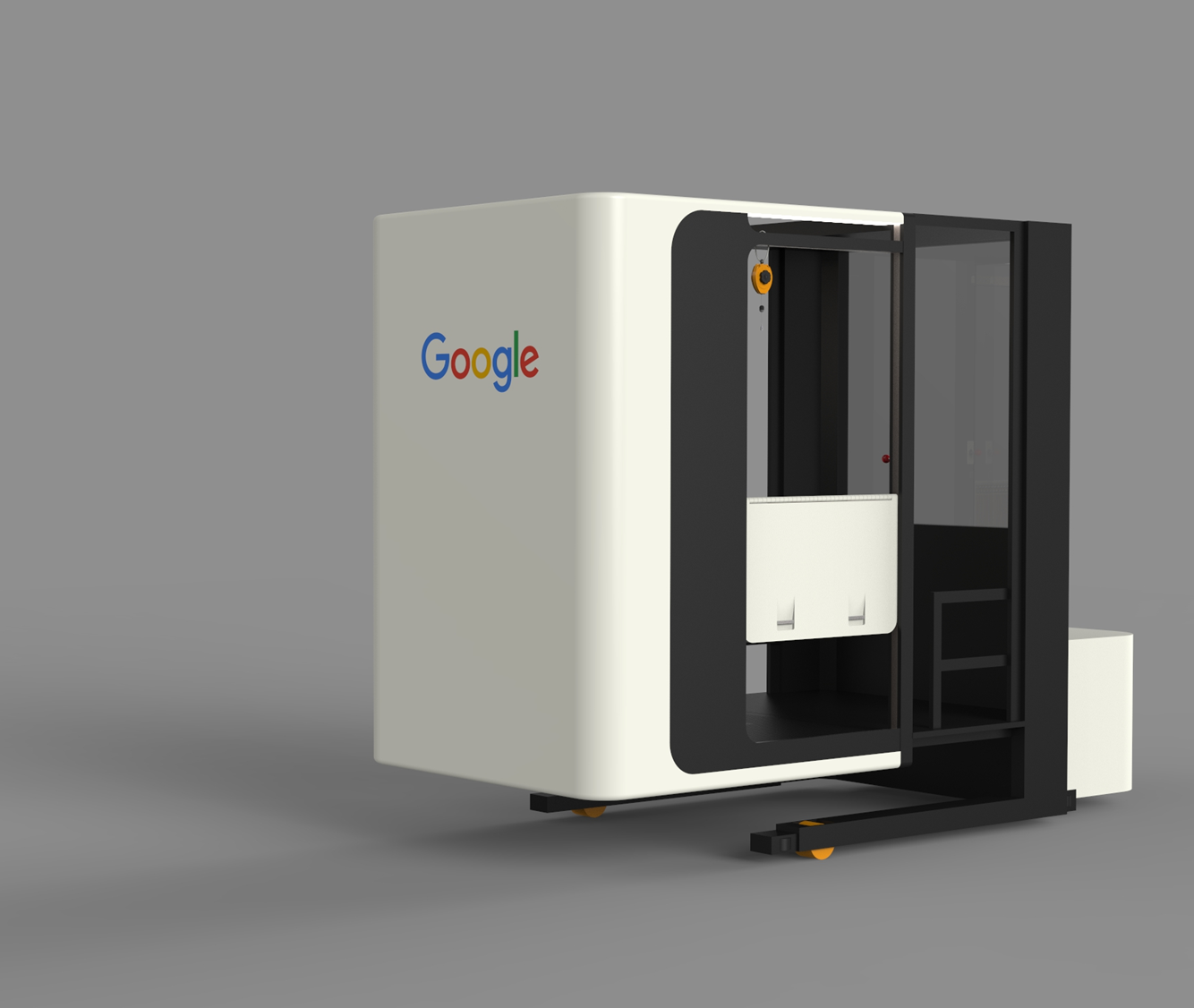

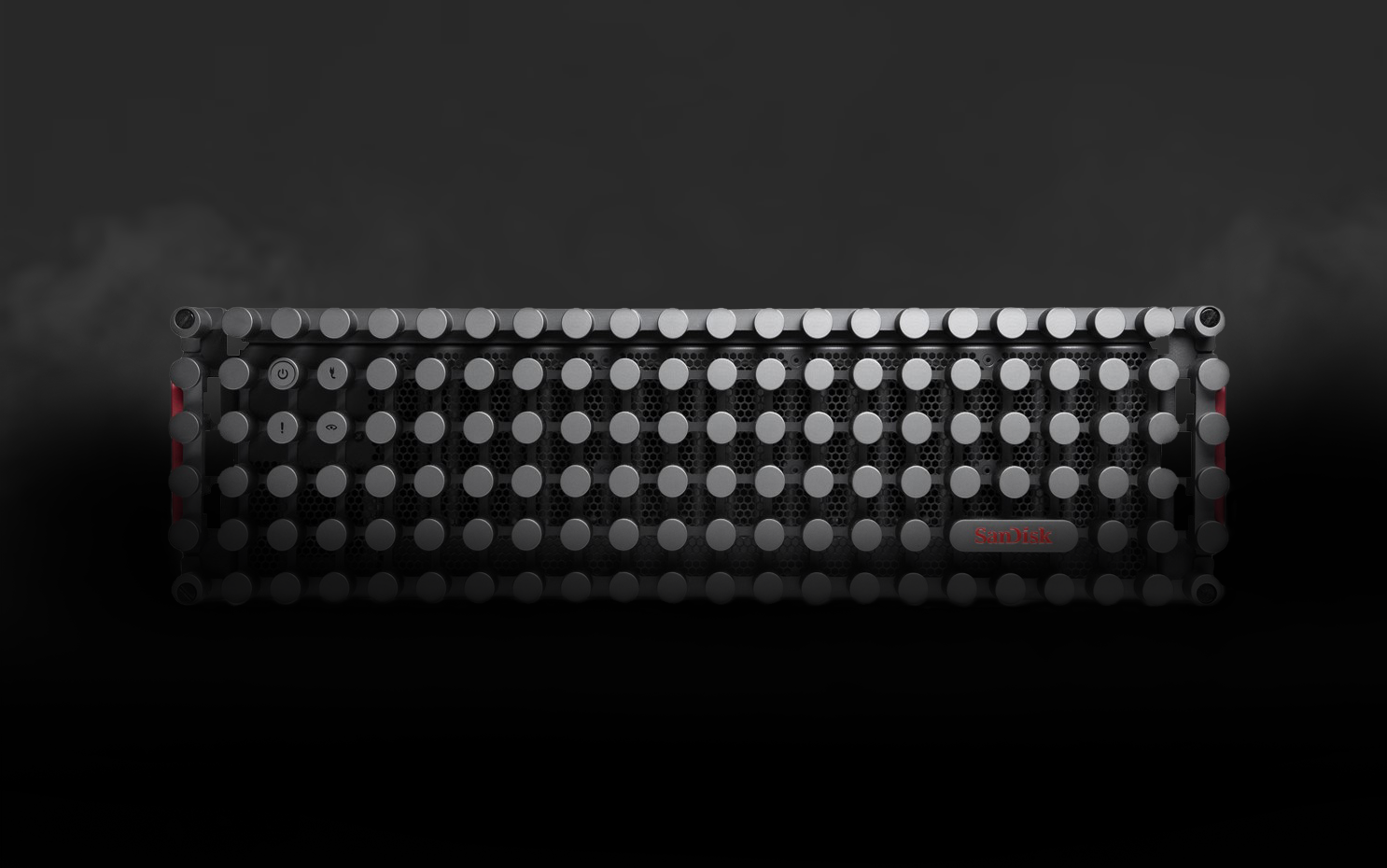

Industrial & Enterprise Equipment

The success of industrial products depends on how well the requirements are met. Acorn Product Development has been designing, engineering, testing, and providing production support for industrial products globally since its inception 30 years ago. Our development process ensures precision, reliability, safety, and manufacturability. As a leader in industrial product development with an international manufacturing network, we provide fast development cycles while meeting your cost, functionality, and quality requirements. Our expertise in industrial product development covers the following:

Testing Equipment and System

Manufacturing Equipment

Servers and Switches

Enterprise Hardware

Rackmount Solutions

Power Generator

Production Tools and Equipment

Industrial Capabilities

Our end-to-end, customized process enables our team to develop, design, prototype, test, and manufacture under one roof. With unparalleled industry-leading experiences, our industrial product development capabilities include:

Mechanical engineering

HW System Architecture Development

System Build, Testing & Qualification

System Layout Design

Complex Mechanism Design

Embedded Electronics & Firmware Development

PCB Design & Bring-Up

System Cabling Design & Documentation

BOM & Full Documents Package

Industrial Design

User Interface Design (UI / UX)

Human Factors, HRI & Ergonomics Analysis

Prototyping

Component and Vendor Sourcing

Manufacturing and Production Support

Full Industrial Services

With a steadfast commitment to meeting and exceeding industrial standards, we are your partners in crafting exceptional solutions. Our seasoned team of designers and engineers is poised to bring your product from concept to realization.

From intricate technical specifications to seamless manufacturability, we're equipped to navigate every challenge!

Factors of Industrial and Enterprise Equipment Design

In addition to good engineering and design, there are a number of imperative factors to consider when developing industrial and enterprise equipment. At Acorn, we use a multifaceted approach to ensure that our design considerations extend beyond the obvious, encompassing factors such as regulatory compliance, supply chain intricacies, and emerging technologies. We specialize in navigating the intricate landscape of product development, bringing a wealth of expertise to the table that goes beyond individual or in-house capabilities. By leveraging our 30 years of experience, one can tap into a reservoir of knowledge, ultimately leading to the creation of industrial and enterprise equipment that is functionally robust and poised for success in a competitive market.

Prototyping

Make prototyping and design validation as part of the iterative process early.

Test functionality, performance, precision, and reliability with users.

Validate and refine requirements based on findings if needed.

Safety

Understand and comply with industry safety standards and regulations.

Perform risk analysis and ergonomics tests early and often.

Implement easily accessible fail-safe features and emergency stop measures.

Cost

Use prototypes to estimate the cost of materials, manufacturing, and assembly.

Identify and prioritize direct and indirect costs at each phase.

Account for quality assurance and compliance costs over the product’s life.

Materials

Use materials that comply with standards, and regulations to ensure safety.

Consider DFM factors, fabrication processing, cost, and resource availability.

Prioritize recyclable material with minimal environmental impact.

Lifecycle

Include maintenance, upgrades, and disposal of the equipment.

Estimate cost and effort for support, modification, and decommissioning.

Proper disposal to minimize environmental impact and meet all regulations.

Improvement

Collect feedback from end users and stakeholders frequently.

Identify and course-correct issues to meet requirements and standards.

Continuously monitor and improve the quality and performance.